Agile Manufacturing

COSMIAC has a rich and robust history in the field of prototype manufacturing. Over the past twelve years, COSMIAC has been funded to perform extensive research by the Air Force Research Laboratory, the National Aeronautics and Space Administration, and the National Additive Manufacturing Innovation Institute. These organizations have funded COSMIAC to perform research in the following areas:

- Materials Testing

- Radiation Testing

- Thermal Management

- Workforce Development

- RF Systems

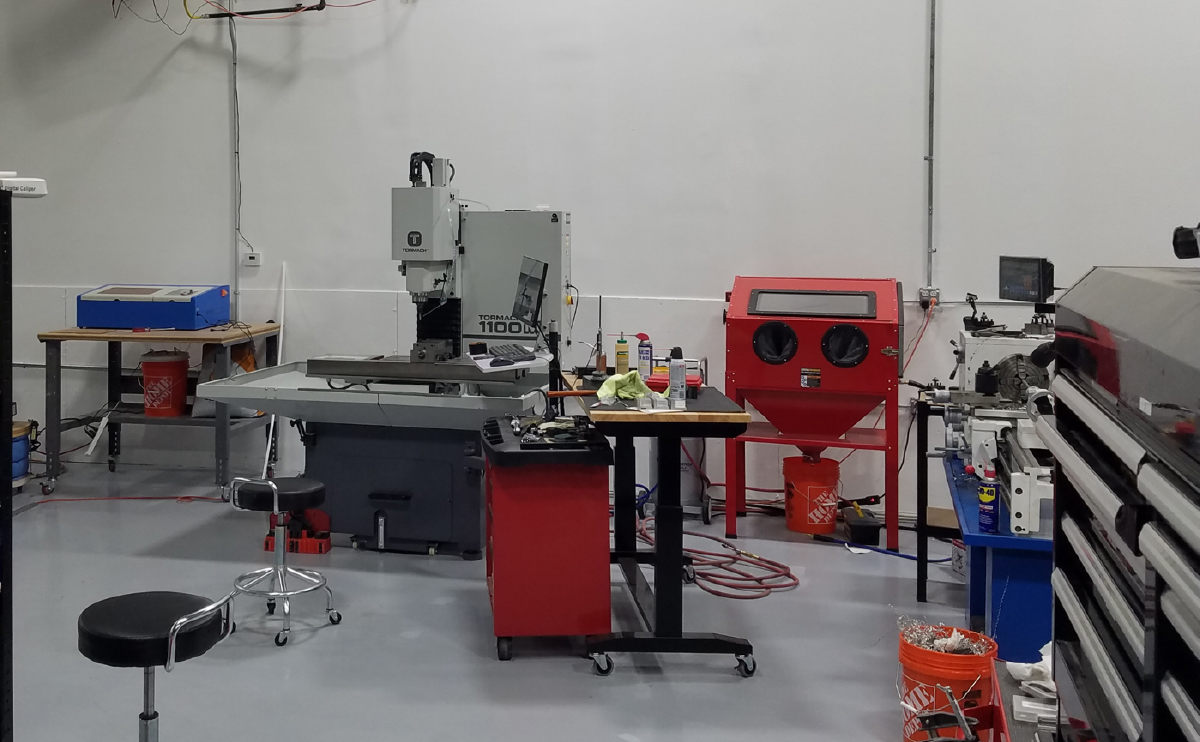

COSMIAC has a full line of additive and subtractive manufacturing capabilities. This include milling, lathing and a full line of thermal vacuum capabilities. The COSMIAC cleanroom provides the ability to do integration, assembly, and test at the class 1000 level.

Above: COSMIAC Cleanroom

Above: Manufacturing in the COSMIAC Launchpad

Flying the Raspberry Pi and the Beaglebone Black into Orbit from Alasdair Allan on Vimeo.

For 3D printing, COSMIAC has fourteen different printing solutions that provide capabilities to print a wide range of materials with different precision levels. Recent work involved printing personal protective equipment for the state of New Mexico. The COSMIAC team is also involved with rendering objects into different formats for printing, virtual (and augmented) reality. Additionally, the printing of high-temperature materials for space applications is possible.

COSMIAC's 3D printing efforts were featured in Makezine, at the 2015 SmallSat conference in Logan, Utah.

3D Printing at COSMIAC from COSMIAC on Vimeo.

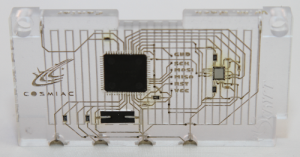

Examples of COSMIAC's 3D printing

Above: 3D-printed circuit board flown on COSMIAC's Trailblazer satellite

Above: Thermal Vacuum Capabilities at COSMIAC

Above: Milling and Machining Capabilities